(一)、圆钢切断机厂家维护保养

(一)、圆钢切断机厂家维护保养(1) Maintenance of round steel cutter manufacturers

1.每班保养(每班工作前、工作中和工作后进行)1

1. Maintenance of each shift (before, during and after work)1

(1)清洁机体,按润滑表加注规定的油料.

(1) Clean the body and fill the prescribed oil according to the lubrication table.

(2)检查各部螺栓,不得缺损,要紧固牢靠.三角皮带的松紧度以能在皮带中间按下10~15毫米为宜,各防护装置要齐全完好.

(2) Inspection bolts, not defective, must be firmly fastened. Triangular belt tightness to be able to press 10-15 mm in the middle of the belt is appropriate, the protective devices should be complete and intact.

(3)检查电路和开关,线头应连接牢固,保险丝应符合规定,开关接触应可靠,接地应良好.

(3) Check the circuit and switch, the wire head should be firmly connected, the fuse should comply with the regulations, the switch contact should be reliable, and the grounding should be good.

(4)调整固定刀片和活动刀片的间隙,两刀片的重叠量在正常情况下为2毫米,间隙应不大于0.3毫米.

(4) Adjust the clearance between the fixed blade and the movable blade. The overlap between the two blades is 2 mm under normal conditions, and the clearance should be no more than 0.3 mm.

(5)刀片固定架的螺栓不得松动,如刀口磨钝应予更换.

(5) The bolts of the blade fixing frame shall not be loosened. If the edge of the blade is blunt, it shall be replaced.

(6)检查离合器,接触应平稳,分离应完全.

(6) Check clutch, contact should be smooth, separation should be complete.

(7)用手转动2~3圈进行试运转,各部灵活无阻后,再接通电源运转1~2分钟,各部应工作正常,无异常声响.

(7) Turn 2-3 circles by hand for trial operation. After each part is flexible and unimpeded, turn on the power supply and run for 1-2 minutes. Each part should work normally without abnormal sound.

(8)在运转中检查轴承温度,滚动轴承及滑动轴承的温度不应高于600C,电动机的温升不应超过600C.

(8) Check the temperature of bearings in operation. The temperature of rolling bearings and sliding bearings should not be higher than 600C, and the temperature rise of motors should not exceed 600C.

(二)、一级保养(每隔400工作小进度进行)

(2) Level I Maintenance (small progress every 400 jobs)

(1)进行每班保养的全部工作.

(1) Conduct all maintenance work for each shift.

(2)测量电机绝缘电阻值和拆检电动机.电机绝缘阻值不应低于0.5兆欧,否则应予以干燥,拆检电动机,清除定子绕组上的灰尘,检查定子和转子间有无摩擦痕迹,清洗轴承,加注新润滑脂.

(2) Measure the insulation resistance of the motor and dismantle the motor. The insulation resistance of the motor should not be less than 0.5 megaoh. Otherwise, the motor should be dried, dismantled and inspected, the dust on the stator winding should be removed, the friction marks between the stator and the rotor should be checked, the bearings should be cleaned, and the new grease should be added.

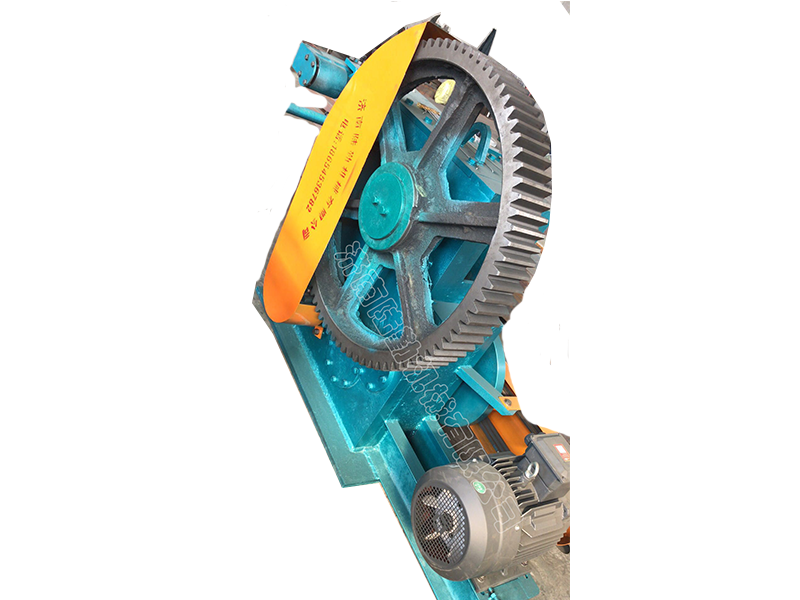

(3)拆检各传动零件,清洗油污.检查齿轮、轴承和偏心体的磨损程度,齿轮侧面向间隙应不大于1.7毫米,滑动轴承径向间隙不应大于0.4毫米,偏心体与滑板座之间的间隙应不大于0.5毫米.加注新润滑油.

(3) dismantle and inspect all transmission parts and clean oil stains. Check the wear degree of gear, bearing and eccentric body. The lateral clearance of gear shall not be greater than 1.7mm, the radial clearance of sliding bearing shall not be greater than 0.4mm, and the clearance between eccentric body and sliding plate seat shall not be greater than 0.5mm. Add new lubricating oil.

(4)检查滑板和滑板座表面磨损情况,滑板与滑板座纵向游动间隙不得大于0.5毫米,横向间隙不得大于0.2毫米.

(4) Check the surface wear of the skateboard and the skateboard seat. The longitudinal swimming clearance between the skateboard and the skateboard seat shall not be greater than 0.5 mm, and the lateral clearance shall not be greater than 0.2 mm.http://www.luqinjixie.com